CSK Head Machine Screw

Price 0.30 INR/ Piece

MOQ : 2000 Pieces

CSK Head Machine Screw Specification

- Surface Treatment

- Plated / Coated

- Corrosion Protection

- Yes, through coated finish

- Usage

- Industrial

- Material

- Stainless Steel / Mild Steel

- Type

- Machine Screw

- Quality Level

- Industrial Grade

- Product Type

- CSK Head Machine Screw

- Head Shape Type

- Countersunk (CSK) Head

- Color

- Silver

- Head Size

- Varies (Commonly M3 to M8)

- Screw Size

- Customizable as per requirement

- Finish

- Coated

- Drive Type

- Slotted / Phillips

- Standard

- IS, DIN, or as per client requirement

- Thread Type

- Metric / Imperial (as per specification)

- Length

- 10mm - 100mm (customizable)

- Hardness

- As per grade specifications

CSK Head Machine Screw Trade Information

- Minimum Order Quantity

- 2000 Pieces

- FOB Port

- Delhi

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 200000 Pieces Per Month

- Delivery Time

- 7-10 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About CSK Head Machine Screw

We, Tayal Screw India, are counted as one of the leading Wholesaler, Supplier & Importer of a wide range of the best quality of Nuts and Bolts, Metal Screw, Machine Tools, Fastener Expansion Tube, Heavy Duty Anchors, General Fixing Anchors, Pipe Clamps, Industrial Screws and many more. Standardized production of products is assured due to our state-of-the-art infrastructural facility set up at Delhi. Known for their seamless finish, resistance against corrosion, dimensional accuracy and sturdy construction, these products are available with us in various dimensions and sizesVersatile Industrial Fastening Solution

Our CSK Head Machine Screws are engineered to deliver reliable fastening in diverse industrial settings. Customizable in length, size, drive type, and threading, they are suitable for machinery assembly, electrical installations, or heavy-duty construction. Their countersunk head design provides a smooth, flush finish after installation.

Enhanced Corrosion Protection & Durability

Manufactured from stainless or mild steel and finished with protective plating or coatings, these screws excel in harsh environments. The coating not only resists corrosion but also strengthens the screw for prolonged service life, making them suitable for demanding industrial operations.

Compliance and Customization as Standard

Adhering to IS, DIN, or specific client requirements, these screws are available in metric or imperial threads with varied drive types. Clients can request custom dimensions, hardness, and finishes, ensuring each screw matches precise application needs and compliance standards.

FAQ's of CSK Head Machine Screw:

Q: How are CSK Head Machine Screws installed and what tools are required?

A: CSK Head Machine Screws are installed by aligning them into pre-drilled holes on the mating surfaces. Depending on the selected drive type, use either a slotted screwdriver or a Phillips screwdriver for proper fastening and a flush fit with the countersunk head.Q: What are the available customization options for these machine screws?

A: Customers can customize screw length (10mm to 100mm), thread type (metric or imperial), drive type (slotted or Phillips), head size (typically M3 to M8), material (stainless steel or mild steel), hardness, and surface finish. Standards compliance and specific screw sizes are also tailored to individual project requirements.Q: When should I choose a coated or plated finish for CSK Head Machine Screws?

A: A coated or plated finish is recommended when the screws will be exposed to corrosive environments, moisture, or chemicals. The finish enhances corrosion resistance, improves durability, and helps maintain the screw's integrity in harsh industrial applications.Q: Where can these machine screws be used?

A: They are primarily designed for industrial use, fitting applications such as machinery assembly, electrical enclosures, automotive components, equipment fabrication, and general construction where flush-mounted fasteners with strong holding power are required.Q: What benefits do CSK Head Machine Screws offer in industrial applications?

A: These screws provide a sleek, flush finish due to their countersunk head, ensuring safety and aesthetic appeal. With robust corrosion protection, customizable features, and industrial-grade quality, they guarantee reliable performance in demanding environments.Q: What is the process for ordering custom CSK Head Machine Screws in India?

A: Ordering involves specifying requirements such as material, dimensions, thread type, finish, and compliance standards. The supplier then manufactures or sources the screws as per the provided specifications, ensuring timely delivery to industrial clients throughout India.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Machine Screw Category

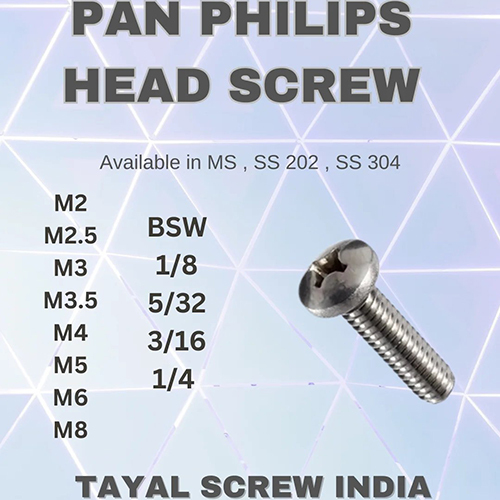

Pan Philips Head Screw

Price 0.5 INR / Piece

Minimum Order Quantity : 1000 Pieces

Color : Silver

Usage : Industrial

Product Type : Pan Philips Head Screw

Finish : Coated

M3 SS Slotted Stud Pointed Pin Screw

Minimum Order Quantity : 1000 Units

Color : Silver

Usage : Industrial

Product Type : Pin Screw

Finish : polished

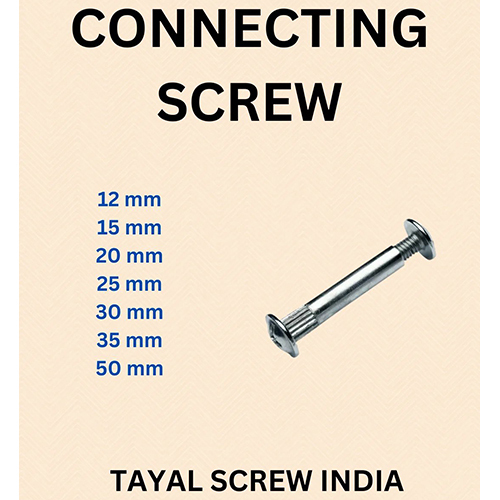

12mm Connecting Screw

Price 2.2 INR / Unit

Minimum Order Quantity : 1000 Units

Color : Silver

Usage : Industrial

Product Type : Connecting Screw

Finish : polished

M3 SS304 Semi Philips Machine Screw

Minimum Order Quantity : 1000 Units

Color : Silver

Usage : Industrial

Product Type : Philips Machine Screw

Finish : polished

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free